Only $1/Month for FaceAzure Online

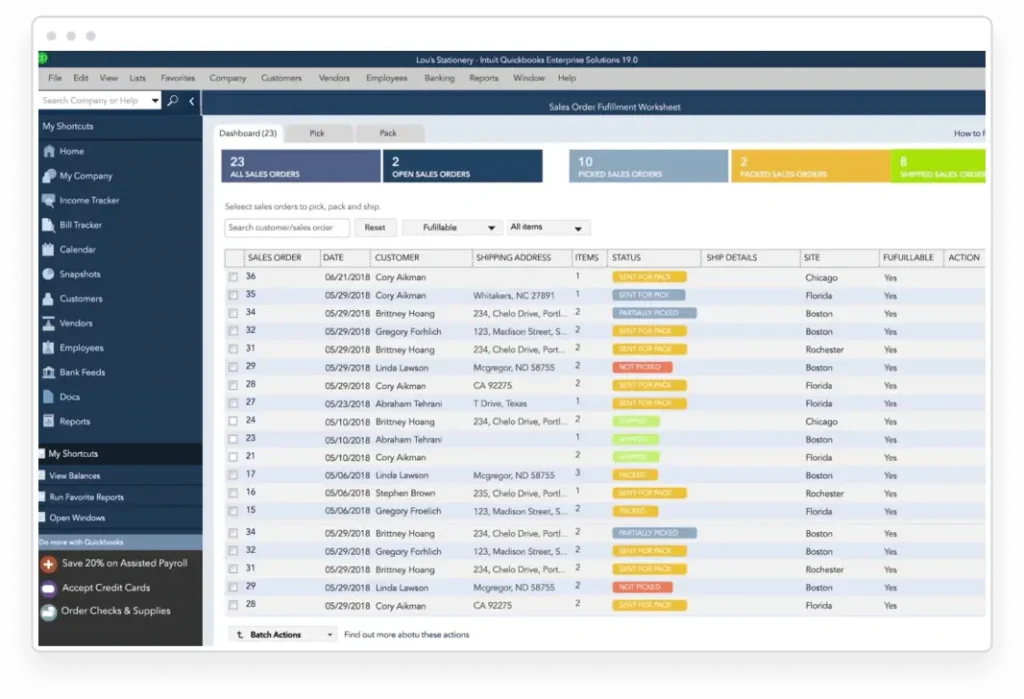

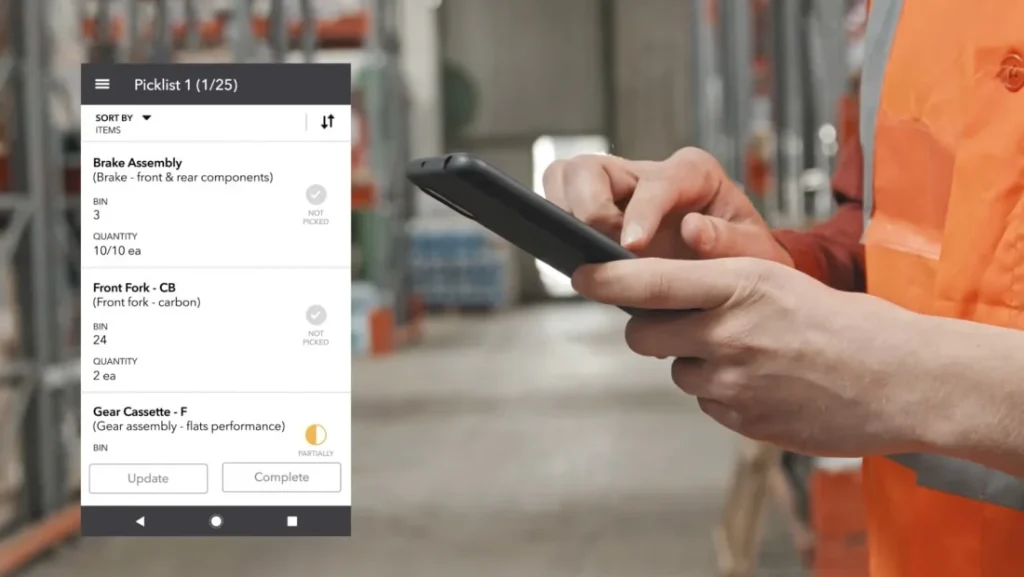

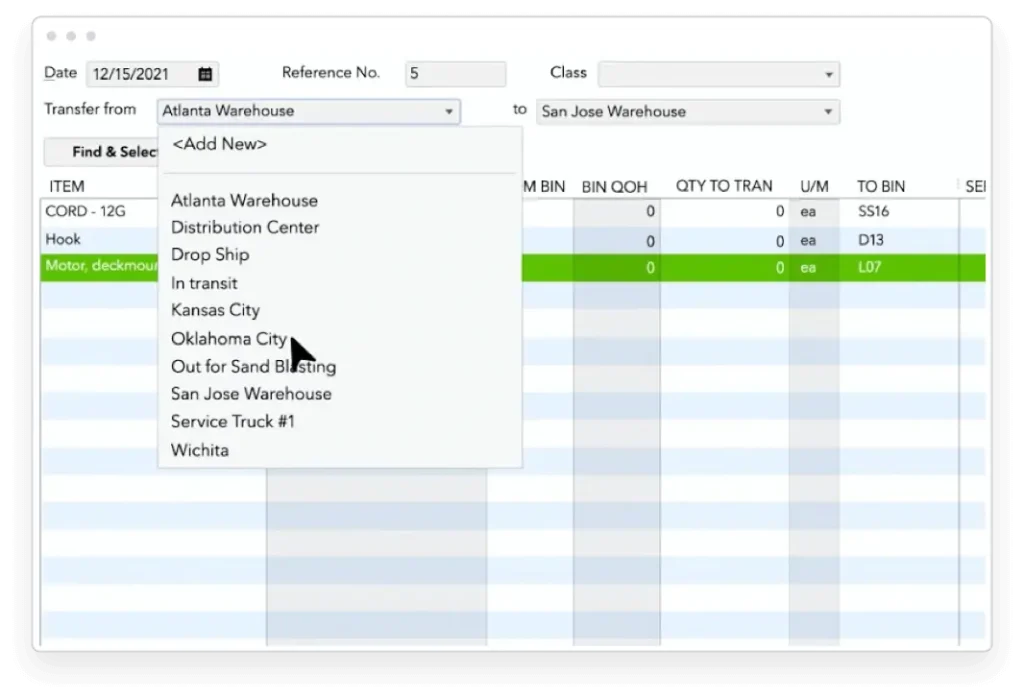

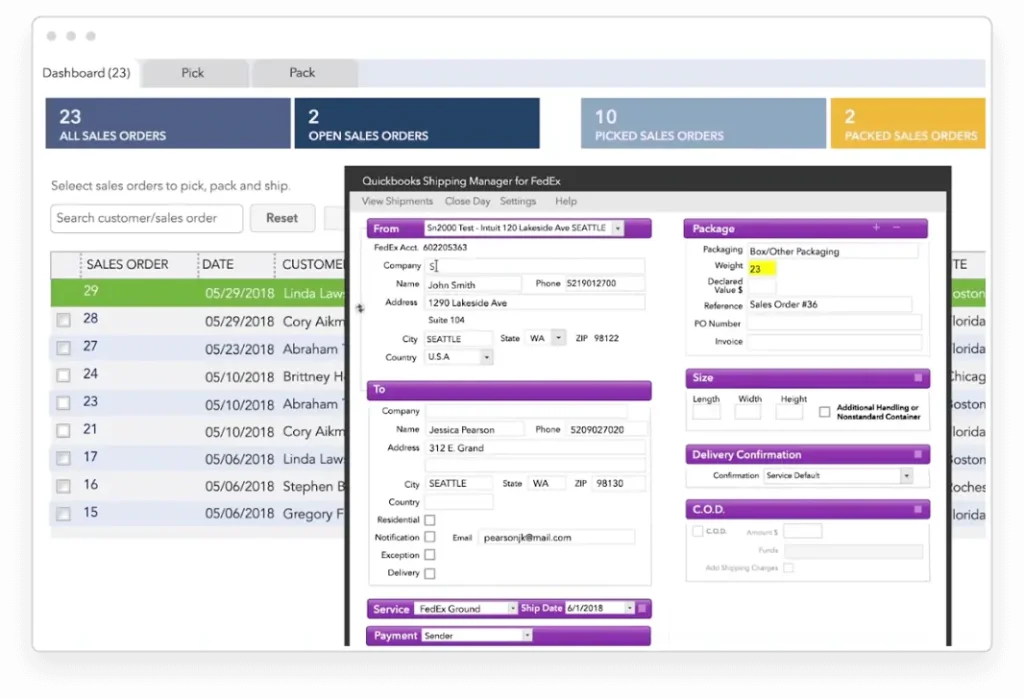

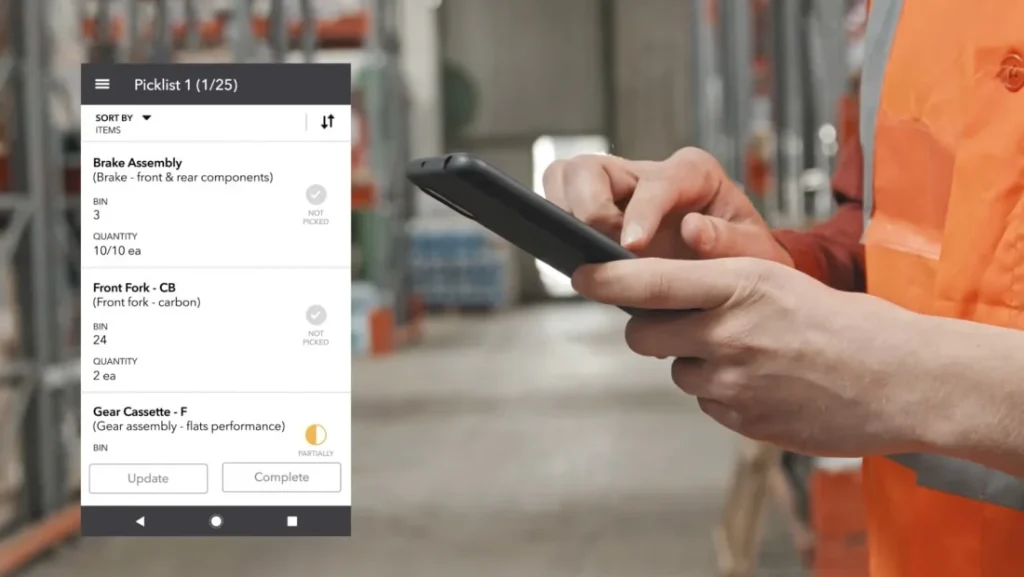

With remote access,* QuickBooks Enterprise can manage inventory, reporting, sales, time tracking, and payroll from anywhere.

Only available in QuickBooks Enterprise Platinum and Diamond

All Rights Reserved. Terms of Use | Privacy Policy